A comprehensive assessment of state-wise biogas potential and its utilization in India

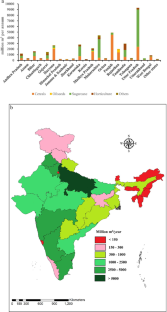

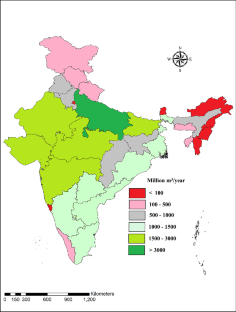

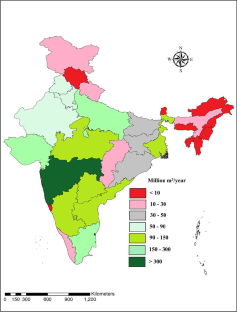

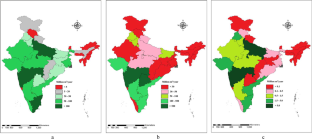

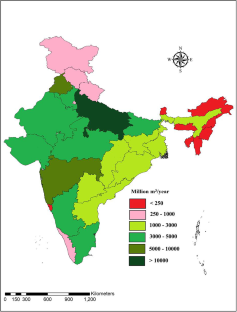

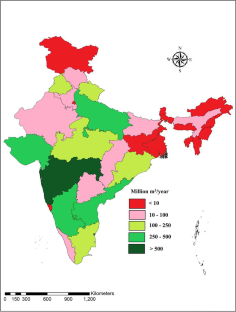

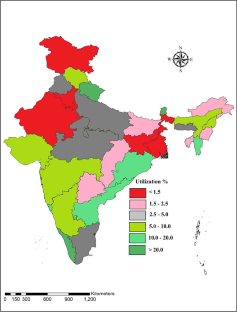

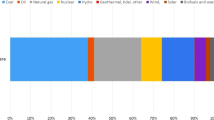

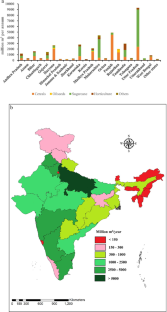

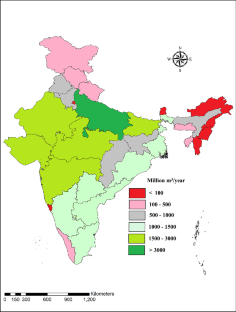

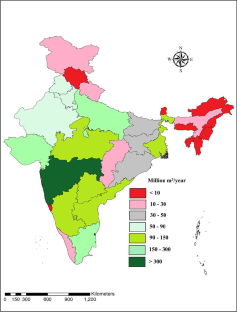

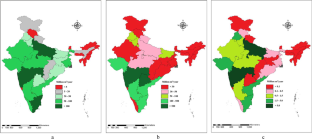

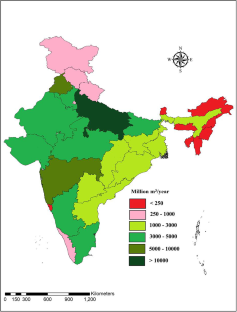

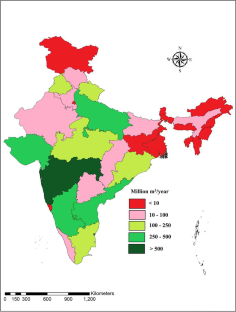

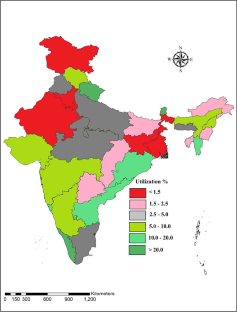

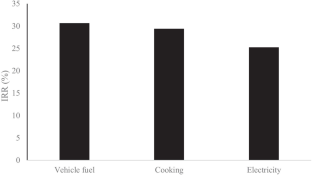

Conventional sources of energy like fossil fuels are available in limited quantities and harm environment. So, for sustainable growth, renewable energy is the only way forward. Biomass-based energy has untapped potential and is one of the most economical and best-proven options among the various alternative energy sources available. To fully utilize the biomass, the estimation of the possible potential is much needed. A state-wise biomass database is valuable for localized bioenergy policy. However, in India, a state-level biomass resource database is inadequate. This paper assessed the state-wise potential of biogas from various of sources including crop residues, livestock and poultry wastes, municipal solid wastes, and wastewater (sewage and industrial). The overall estimated biogas potential from organic waste in India is 74.795 billion m 3 /year. Also, the state-wise current generation capacity of digesters installed under various schemes is assessed in this paper. Currently, digesters with a generation capacity of 3.635 billion m 3 /year are achieved in India. The results show that there is a massive gap between the potential and its utilization. Among all the states, Uttar Pradesh (14.73 billion m 3 /year) has the highest biogas potential, and Maharashtra (671.40 million m 3 /year) has the highest installed achievement. The statistics generated in this research is expected to be beneficial for decentralized biogas planning and management in the state.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Subscribe and save

Springer+ Basic

€32.70 /Month

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

Buy Now

Price includes VAT (France)

Instant access to the full article PDF.

Rent this article via DeepDyve

Similar content being viewed by others

Zone-wise biogas potential in India: fundamentals, challenges, and policy considerations

Article 08 December 2023

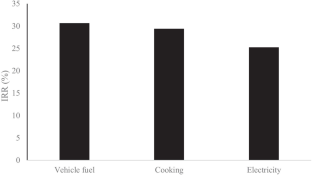

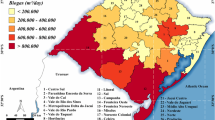

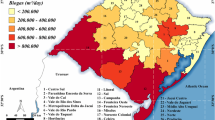

Biomass availability assessment for biogas or methane production in Rio Grande do Sul, Brazil

Article 01 June 2019

Potential for the production of biofuels from agricultural waste, livestock, and slaughterhouse waste in Golestan province, Iran

Article 24 January 2021

Explore related subjects

Abbreviations

Municipal solid waste

National Project on Biogas Development

Khadi and Villages Industries Commission

Action for Food Production

Biogas Power Generation Program

Biogas Power Generation (Off-grid) and Thermal Energy Application Program

National Biogas and Manure Management Program

New National Biogas and Organic Manure Program

Sustainable Alternative Towards Affordable Transportation

Hydraulic retention time

Million liter per day

Centre pollution control board

Chemical oxygen demand

Biological oxygen demand

Ministry of Renewable Energy

Crop production of an ith crop at sth state

Crop area of the ith crop at sth state

Crop yield of ith crop

Gross residue production of the ith crop at sth state

Residue to crop ratio of ith crop

Surplus residue production of the ith crop at sth state

Collection efficiency of the ith crop at sth state

Biogas yield of ith crop

Biogas potential of the ith crop at sth state

Biogas potential from crop residue at sth state

Dung production of ith animal at sth state

Animal population of ith animal at sth state

Dung per day of ith animal

Surplus dung available of ith animal at sth state

Collection efficiency of ith animal

Biogas potential from animal waste at sth state

Available municipal solid waste at sth state

Municipal solid waste at sth state

Organic fraction of municipal solid waste at sth state

Biogas potential from available municipal solid waste at sth state

Biogas potential from sewage

Removal efficiency of wastewater

Total biogas potential of India

References

- Thomas P, Soren N, Rumjit NP, George James J, Saravanakumar MP (2017) Biomass resources and potential of anaerobic digestion in Indian scenario. Renew Sustain Energy Rev 77:718–730. https://doi.org/10.1016/j.rser.2017.04.053ArticleGoogle Scholar

- MoP, Power Sector at a Glance ALL INDIA | Government of India | Ministry of Power, (2020). https://powermin.gov.in/en/content/power-sector-glance-all-india (accessed August 10, 2020).

- Rao PV, Baral SS, Dey R, Mutnuri S (2010) Biogas generation potential by anaerobic digestion for sustainable energy development in India. Renew Sustain Energy Rev 14:2086–2094. https://doi.org/10.1016/j.rser.2010.03.031ArticleGoogle Scholar

- M. Swaminathan, How can India’s waste problem see a systemic change?, Econ. Polit. Wkly. (2018). https://www.epw.in/engage/article/institutional-framework-implementing-solid-waste-management-india-macro-analysis (accessed April 9, 2020).

- Unnikrishnan S, Singh A (2010) Energy recovery in solid waste management through CDM in India and other countries. Resour Conserv Recycl 54:630–640. https://doi.org/10.1016/j.resconrec.2009.11.003ArticleGoogle Scholar

- Styles D, Dominguez EM, Chadwick D (2016) Environmental balance of the of the UK biogas sector: an evaluation by consequential life cycle assessment. Sci Total Environ 560–561:241–253. https://doi.org/10.1016/j.scitotenv.2016.03.236ArticleGoogle Scholar

- K. Ostrem, N.J. Themelis, Greening waste: anaerobic digestion for treating the organic fraction of municipal solid wastes., 2004.

- Angelidaki I, Sanders W (2004) Assessment of the anaerobic biodegradability of macropollutants. Rev Environ Sci Biotechnol 3:117–129. https://doi.org/10.1007/s11157-004-2502-3ArticleGoogle Scholar

- Krishania M, Kumar V, Vijay VK, Malik A (2013) Analysis of different techniques used for improvement of biomethanation process: a review. Fuel 106:1–9. https://doi.org/10.1016/j.fuel.2012.12.007ArticleGoogle Scholar

- Kondusamy D, Kalamdhad AS (2014) Pre-treatment and anaerobic digestion of food waste for high rate methane production-a review. J Environ Chem Eng 2:1821–1830. https://doi.org/10.1016/j.jece.2014.07.024ArticleGoogle Scholar

- Yadvika, Santosh TR, Sreekrishnan S, Kohli V. Rana (2004) Enhancement of biogas production from solid substrates using different techniques-a review. Bioresour Technol 95:1–10. https://doi.org/10.1016/j.biortech.2004.02.010ArticleGoogle Scholar

- Scarlat N, Dallemand JF, Fahl F (2018) Biogas: developments and perspectives in Europe. Renew Energy 129:457–472. https://doi.org/10.1016/j.renene.2018.03.006ArticleGoogle Scholar

- Iordan C, Lausselet C, Cherubini F (2016) Life-cycle assessment of a biogas power plant with application of different climate metrics and inclusion of near-term climate forcers. J Environ Manage 184:517–527. https://doi.org/10.1016/j.jenvman.2016.10.030ArticleGoogle Scholar

- Motghare KA, Rathod AP, Wasewar KL, Labhsetwar NK (2016) Comparative study of different waste biomass for energy application. Waste Manag 47:40–45. https://doi.org/10.1016/j.wasman.2015.07.032ArticleGoogle Scholar

- Sfez S, De Meester S, Dewulf J (2017) Co-digestion of rice straw and cow dung to supply cooking fuel and fertilizers in rural India: impact on human health, resource flows and climate change. Sci Total Environ 609:1600–1615. https://doi.org/10.1016/j.scitotenv.2017.07.150ArticleGoogle Scholar

- S.K. Khanal, Anaerobic biotechnology for bioenergy production: principles and applications, 2011. https://books.google.co.in/books?hl=en&lr=&id=1RbyLx-GkSMC&oi=fnd&pg=PT7&dq=Khanal,+S.K.,+2008.+Anaerobic+biotechnology+for+bioenergy+production:+principles+and+applications.+John+Wiley+%26+Sons+Inc,+Ames,+Iowa,+United+States.&ots=oUU8ojbnRG&sig=F5Ktn1GJ9 (accessed August 10, 2020).

- Abbasi T, Tauseef SM, Abbasi SA (2012) A brief history of anaerobic digestion and “biogas.” Biogas energy. Springer, New York, pp 11–23. https://doi.org/10.1007/978-1-4614-1040-9_2ChapterGoogle Scholar

- Singh KJ, Sooch SS (2004) Comparative study of economics of different models of family size biogas plants for state of Punjab, India. Energy Convers Manag 45:1329–1341. https://doi.org/10.1016/j.enconman.2003.09.018ArticleGoogle Scholar

- Kumar A, Mandal B, Sharma A (2015) Advancement in biogas digester. Green Energy Technol 201:351–382. https://doi.org/10.1007/978-81-322-2337-5_14ArticleGoogle Scholar

- Schemes | Ministry of New and Renewable Energy, Government of India, (n.d.). https://mnre.gov.in/bio-energy/schemes (accessed August 10, 2020).

- Swachh Bharat Mission-Gobar-Dhan, (n.d.). https://sbm.gov.in/Gobardhan/SLRM_AboutUs.aspx (accessed August 10, 2020).

- MOP&NG, SATAT, (2018). https://www.iocl.com/Satat.aspx (accessed August 10, 2020).

- MNRE, Current Status | Ministry of New and Renewable Energy, Government of India, (2020). https://mnre.gov.in/bio-energy/current-status (accessed August 10, 2020).

- Sukhesh MJ, Rao PV (2018) Anaerobic digestion of crop residues: technological developments and environmental impact in the Indian context, Biocatal. Agric. Biotechnol 16:513–528. https://doi.org/10.1016/j.bcab.2018.08.007ArticleGoogle Scholar

- Kaur G, Brar YS, Kothari DP (2017) Potential of livestock generated biomass: untapped energy source in India. Energies 10:1–15. https://doi.org/10.3390/en10070847ArticleGoogle Scholar

- Ramachandra TV, Shruthi BV (2007) Spatial mapping of renewable energy potential. Renew Sustain Energy Rev 11:1460–1480. https://doi.org/10.1016/j.rser.2005.12.002ArticleGoogle Scholar

- Das S, Jash T (2009) District-level biomass resource assessment: a case study of an Indian State West Bengal. Biomass Bioenerg 33:137–143. https://doi.org/10.1016/j.biombioe.2008.05.001ArticleGoogle Scholar

- Singh J, Panesar BS, Sharma SK (2008) Energy potential through agricultural biomass using geographical information system-a case study of Punjab. Biomass Bioenerg 32:301–307. https://doi.org/10.1016/j.biombioe.2007.10.003ArticleGoogle Scholar

- Aich A, Ghosh SK (2016) Organic fraction of municipal solid waste–a valuable source of green energy in India. Int J Energy Sect Manag 10:526–545. https://doi.org/10.1108/IJESM-06-2015-0001ArticleGoogle Scholar

- Lata K, Kansal A, Balakrishnan M, Rajeshwari KV, Kishore VVN (2002) Assessment of biomethanation potential of selected industrial organic effluents in India. Resour Conserv Recycl 35:147–161. https://doi.org/10.1016/S0921-3449(01)00112-4ArticleGoogle Scholar

- Cardoen D, Joshi P, Diels L, Sarma PM, Pant D (2015) Agriculture biomass in India: part 1. Estimation and characterization. Resour Conserv Recycl 102:39–48. https://doi.org/10.1016/j.resconrec.2015.06.003ArticleGoogle Scholar

- Kshirsagar MP, Arora A, Chandra H (2012) Estimation of anaerobic codigestion potential of agri-waste in India and comparative financial analysis. Int J Sustain Energy 31:175–188. https://doi.org/10.1080/1478646X.2011.555819ArticleGoogle Scholar

- Dhar H, Kumar S, Kumar R (2017) A review on organic waste to energy systems in India. Bioresour Technol 245:1229–1237. https://doi.org/10.1016/j.biortech.2017.08.159ArticleGoogle Scholar

- Vadrevu K, Lasko K (2015) Fire regimes and potential bioenergy loss from agricultural lands in the Indo-Gangetic Plains. J Environ Manage 148:10–20. https://doi.org/10.1016/j.jenvman.2013.12.026ArticleGoogle Scholar

- Ravindranath NH, Somashekar HI, Nagaraja MS, Sudha P, Sangeetha G, Bhattacharya SC, Abdul Salam P (2005) Assessment of sustainable non-plantation biomass resources potential for energy in India. Biomass Bioenergy. 29:178–190. https://doi.org/10.1016/j.biombioe.2005.03.005ArticleGoogle Scholar

- Lohan SK, Jat HS, Yadav AK, Sidhu HS, Jat ML, Choudhary M, Peter JK, Sharma PC (2018) Burning issues of paddy residue management in north-west states of India. Renew Sustain Energy Rev 81:693–706. https://doi.org/10.1016/j.rser.2017.08.057ArticleGoogle Scholar

- Mittal S, Ahlgren EO, Shukla PR (2019) Future biogas resource potential in India: a bottom-up analysis. Renew Energy 141:379–389. https://doi.org/10.1016/j.renene.2019.03.133ArticleGoogle Scholar

- Breitenmoser L, Dhar H, Gross T, Bakre M, Huesch R, Hugi C, Wintgens T, Kumar R, Kumar S (2018) Methane potential from municipal biowaste: insights from six communities in Maharashtra, India. Bioresour Technol 254:224–230. https://doi.org/10.1016/j.biortech.2018.01.074ArticleGoogle Scholar

- Elango D, Pulikesi M, Baskaralingam P, Ramamurthi V, Sivanesan S (2007) Production of biogas from municipal solid waste with domestic sewage. J Hazard Mater 141:301–304. https://doi.org/10.1016/j.jhazmat.2006.07.003ArticleGoogle Scholar

- Acharya BK, Mohana S, Madamwar D (2008) Anaerobic treatment of distillery spent wash-a study on upflow anaerobic fixed film bioreactor. Bioresour Technol 99:4621–4626. https://doi.org/10.1016/j.biortech.2007.06.060ArticleGoogle Scholar

- Thompson G, Swain J, Kay M, Forster CF (2001) The treatment of pulp and paper mill effluent: a review. Bioresour Technol 77:275–286. https://doi.org/10.1016/S0960-8524(00)00060-2ArticleGoogle Scholar

- Shukla GL, Prabhu KA (1995) Bio-gas production from sugarcane biomass and agro-industrial waste. Sugarcane Agro-Industr Altern 1:157–170 Google Scholar

- MoSPI, AGRICULTURE - Statistical Year Book India 2018 | Ministry of Statistics and Program Implementation | Government Of India, (2018). http://mospi.nic.in/statistical-year-book-india/2018/177 (accessed December 2, 2019).

- Hiloidhari M, Das D, Baruah DC (2014) Bioenergy potential from crop residue biomass in India. Renew Sustain Energy Rev 32:504–512. https://doi.org/10.1016/j.rser.2014.01.025ArticleGoogle Scholar

- DADF, Chapter 1 Technical note on the 19th livestock census, (2012). http://dadf.gov.in/sites/default/filess/VolumeI.pdf (accessed August 10, 2020).

- MoHUA, State-wise status of implementation of various components under SBM upto January 2020, (2020). http://swachhbharaturban.gov.in/writereaddata/Statewise_status_of_implementation.pdf (accessed August 10, 2020).

- CPCB (2017) Annual Review Report 2015–16, Cent. Pollution Control Board. Minist Environ For Clim Chang 24:1–28 Google Scholar

- MoE&F, National status of waste water generation & treatment: SulabhENVIS Centre, (2021). http://www.sulabhenvis.nic.in/Database/STST_wastewater_2090.aspx (accessed August 10, 2020).

- Khan AA, Gaur RZ, Mehrotra I, Diamantis V, Lew B, Kazmi AA (2014) Performance assessment of different STPs based on UASB followed by aerobic post treatment systems. J Environ Heal Sci Eng 12:43. https://doi.org/10.1186/2052-336X-12-43ArticleGoogle Scholar

- Indiastat, Socio-economic statistical data and facts about India : Indiastat, (2021). https://www.indiastat.com/ (accessed July 21, 2021).

- Turgut SS, Feyissa AH, Küçüköner E, Karacabey E (2021) Uncertainty and sensitivity analysis by Monte Carlo simulation: recovery of trans-resveratrol from grape cane by pressurised low polarity water system. J Food Eng 292:110366. https://doi.org/10.1016/j.jfoodeng.2020.110366ArticleGoogle Scholar

- Gebrezgabher SA, Meuwissen MPM, Oude Lansink AGJM (2012) Energy-neutral dairy chain in the Netherlands: an economic feasibility analysis. Biomass Bioenergy 36:60–68. https://doi.org/10.1016/j.biombioe.2011.10.006ArticleGoogle Scholar

- Saltelli A, Ratto M, Andres T, Campolongo F, Cariboni J, Gatelli D, Saisana M, Tarantola S (2008) Global Sensitivity Analysis The Primer. https://doi.org/10.1002/9780470725184BookMATHGoogle Scholar

- MNRE (2018) Ministry of New and Renewable Energy Annual Report 2018–19. https://doi.org/10.1355/9789812308702-004.

- MoP, Ministry of Power, (2018) 5–14. https://powermin.nic.in/sites/default/files/uploads/ (accessed December 1, 2019).

- Raha D, Mahanta P, Clarke ML (2014) The implementation of decentralised biogas plants in Assam, NE India: the impact and effectiveness of the National Biogas and Manure Management Programme. Energy Policy 68:80–91. https://doi.org/10.1016/j.enpol.2013.12.048ArticleGoogle Scholar

- Nautiyal S, Goswami M, Manasi S, Bez P, Bhaskar K, Khan YDI (2015) Potential of manure based biogas to replace conventional and non-conventional fuels in India: Environmental assessment for emission reduction. Manag Environ Qual An Int J 26:3–20. https://doi.org/10.1108/MEQ-04-2013-0034ArticleGoogle Scholar

- Mittal S, Ahlgren EO, Shukla PR (2018) Barriers to biogas dissemination in India: a review. Energy Policy. https://doi.org/10.1016/j.enpol.2017.10.027ArticleGoogle Scholar

- Schmidt TS, Dabur S (2014) Explaining the diffusion of biogas in India: a new functional approach considering national borders and technology transfer. Env Econ Policy Stud 16:171–199. https://doi.org/10.1007/s10018-013-0058-6ArticleGoogle Scholar

- Singh B, Szamosi Z, Siménfalvi Z, Rosas-Casals M (2020) Decentralized biomass for biogas production. Evaluation and potential assessment in Punjab (India). Energy Reports 6:1702–1714. https://doi.org/10.1016/J.EGYR.2020.06.009ArticleGoogle Scholar

- Kothari R, Vashishtha A, Singh HM, Pathak VV, Tyagi VV, Yadav BC, Ashokkumar V, Singh DP (2020) Assessment of Indian bioenergy policy for sustainable environment and its impact for rural India: strategic implementation and challenges. Environ Technol Innov 20:101078. https://doi.org/10.1016/j.eti.2020.101078ArticleGoogle Scholar

- Gross T, Breitenmoser L, Kumar S, Ehrensperger A, Wintgens T, Hugi C (2021) Anaerobic digestion of biowaste in Indian municipalities: effects on energy, fertilizers, water and the local environment. Resour Conserv Recycl 170:105569. https://doi.org/10.1016/J.RESCONREC.2021.105569ArticleGoogle Scholar

- Usmani RA (2020) Potential for energy and biofuel from biomass in India. Renew Energy 155:921–930. https://doi.org/10.1016/J.RENENE.2020.03.146ArticleGoogle Scholar

- Jagtap NJ, Dalvi VH (2021) Feasibility study of bio-methane economy in India. Biomass Bioenerg 149:106059. https://doi.org/10.1016/J.BIOMBIOE.2021.106059ArticleGoogle Scholar

- Nouni MR, Jha P, Sarkhel R, Banerjee C, Tripathi AK, Manna J (2021) Alternative fuels for decarbonisation of road transport sector in India: options, present status, opportunities, and challenges. Fuel 305:121583. https://doi.org/10.1016/J.FUEL.2021.121583ArticleGoogle Scholar

- Singh AD, Upadhyay A, Shrivastava S, Vivekanand V (2020) Life-cycle assessment of sewage sludge-based large-scale biogas plant. Bioresour Technol 309:123373. https://doi.org/10.1016/j.biortech.2020.123373ArticleGoogle Scholar

- Tyagi VK, Kapoor A, Arora P, Banu JR, Das S, Pipesh S, Kazmi AA (2021) Mechanical-biological treatment of municipal solid waste: case study of 100 TPD Goa plant, India. J Environ Manage 292:112741. https://doi.org/10.1016/J.JENVMAN.2021.112741ArticleGoogle Scholar

- Satpathy P, Pradhan C (2020) Biogas as an alternative to stubble burning in India. Biomass Convers Biorefinery 1:1–12. https://doi.org/10.1007/s13399-020-01131-zArticleGoogle Scholar

- S. Bruun, L. Jensen, S.S.-R. and S. Energy, U. 2014, Small-scale household biogas digesters: an option for global warming mitigation or a potential climate bomb?, Renew. Sustain. Energy Rev. (2014). https://www.sciencedirect.com/science/article/pii/S1364032114001543?casa_token=49ULDCHDhyIAAAAA:DAtwesGU5gcBaCSrAjgknutCC79KmrQ7qnV9wl-7bE9CZ9t2ibbbMVPuPQTkWqo76IfKivmH (accessed November 24, 2020).

- Kapoor R, Ghosh P, Kumar M, Sengupta S, Gupta A, Kumar SS, Vijay V, Kumar V, Kumar Vijay V, Pant D (2020) Valorization of agricultural waste for biogas based circular economy in India: a research outlook. Bioresour Technol 304:123036. https://doi.org/10.1016/J.BIORTECH.2020.123036ArticleGoogle Scholar

- Wainaina S, Awasthi MK, Sarsaiya S, Chen H, Singh E, Kumar A, Ravindran B, Awasthi SK, Liu T, Duan Y, Kumar S, Zhang Z, Taherzadeh MJ (2020) Resource recovery and circular economy from organic solid waste using aerobic and anaerobic digestion technologies. Bioresour Technol 301:122778. https://doi.org/10.1016/J.BIORTECH.2020.122778ArticleGoogle Scholar

- Zhang R, Zhang Z (1999) Biogasification of rice straw with an anaerobic-phased solids digester system. Biores Technol 68:235–245 ArticleGoogle Scholar

- Haryanto A, Sugara BP, Telaumbanua M, Rosadi RAB (2018) Anaerobic co-digestion of cow dung and rice straw to produce biogas using semi-continuous flow digester: effect of urea addition. IOP Conf Ser: Earth Environ Sci 147:012032 ArticleGoogle Scholar

- Contreras LM, Schelle H, Sebrango CR, Pereda I (2012) Methane potential and biodegradability of rice straw, rice husk and rice residues from the drying process. Water Sci Technol 65:1142–1149 ArticleGoogle Scholar

- Wang G (2010) Biogas production from energy crops and agriculture residues

- Aqsha A, Tijani MM, Mahinpey N (2014) Catalytic pyrolysis of straw biomasses (wheat, flax, oat and barley straw) and the comparison of their product yields. WIT Trans Ecol Environ 2:1007 ArticleGoogle Scholar

- Deepanraj B, Sivasubramanian V, Jayaraj S (2014) Biogas generation through anaerobic digestion process-an overview. Res J Chem Environ 18:5 Google Scholar

- Kumar S, Gandhi P, Yadav M, Paritosh K, Pareek N, Vivekanand V (2019) Weak alkaline treatment of wheat and pearl millet straw for enhanced biogas production and its economic analysis. Renewable Energy 139:753–764 ArticleGoogle Scholar

- Murphy J, Braun R, Weiland P, Wellinger A (2011) Biogas from crop digestion

- Balsari P, Menardo S, Airoldi G (2011) Effect of physical and thermal pre-treatments on biogas yield of some agricultural by-products yield of some agricultural by-products

- Biogas App - Indian Biogas Association n.d. https://biogas-india.com/service/biogas-app/ (accessed August 11, 2020).

- Zhang Z, Zhang G, Li W, Li C, Xu G (2016) Enhanced biogas production from sorghum stem by co-digestion with cow manure. Int J Hydrogen Energy 41:9153–9158 ArticleGoogle Scholar

- Lehtomäki A, Viinikainen TA, Rintala JA (2008) Screening boreal energy crops and crop residues for methane biofuel production. Biomass Bioenerg 32:541–550 ArticleGoogle Scholar

- Wang C, Hong F, Lu Y, Li X, Liu H (2017) Improved biogas production and biodegradation of oilseed rape straw by using kitchen waste and duck droppings as co-substrates in two-phase anaerobic digestion. PLOS ONE 12:e0182361 ArticleGoogle Scholar

- Braun R, Weiland P, Wellinger A (n.d.) Biogas from energy crop digestion task 37-energy from biogas and landfill gas

- Deng Y, Dai B, Xu J, Liu X, Xu J (2018) Anaerobic co-digestion of rice straw and soybean straw to increase biogas production by pretreatment with trichoderma reesei RUT C30. Environ Progr Sustain Energy 37:1050–1057 ArticleGoogle Scholar

- Kovacic D, Kralik D, Rupcic S, Jovicic D, Spajic R, Tišmac M (2017) Soybean straw, corn stover and sunflower stalk as possible substrates for biogas production in Croatia: a review. Chem Biochem Eng Q 31:187–198 ArticleGoogle Scholar

- Awulu JO, Omale PA, Wonov TJ (2020) Comparative study of methane production from groundnut straw, bambaranut straw and milkweed plant vol. 4

- Eshore S, Mondal C, Das A (2017) Production of biogas from treated sugarcane bagasse. International Journal of Scientific Engineering and Technology 6:224 ArticleGoogle Scholar

- Salomon FotsoSimo W, Nso Jong E, Kapseu C (2016) Improving biogas production of sugarcane bagasse by hydrothermal pretreatment. Chem Biomol Eng 1:21–5 Google Scholar

- Zhang H, Ning Z, Khalid H, Zhang R, Liu G, Chen C (2018) Enhancement of methane production from cotton stalk using different pretreatment techniques. Sci Rep 8:3463 ArticleGoogle Scholar

- Yuan X, Ma L, Wen B, Zhou D, Kuang M, Yang W et al (2016) Enhancing anaerobic digestion of cotton stalk by pretreatment with a microbial consortium (MC1). Biores Technol 207:293–301 ArticleGoogle Scholar

- Kunchikannan LKNV, Mande SP, Kishore VVN, Jain KL (2007) Coir Pith: A potential agro residue for anaerobic digestion. Energy Sources A Recov Utiliz Environ Effects 29:293–301 ArticleGoogle Scholar

- Pisutpaisal N, Boonyawanich S, Saowaluck H (2014) Feasibility of biomethane production from banana peel. Energy Procedia 50:782–788 ArticleGoogle Scholar

- Biogas-Vikaspedia n.d. https://vikaspedia.in/energy/energy-production/bio-energy/biogas (accessed August 11, 2020).

- Kanwar SS, Kalia AK (1993) Anaerobic fermentation of sheep droppings for biogas production. World J Microbiol Biotechnol 9:174–175 ArticleGoogle Scholar

- Khoiyangbam R, Gupta N, Kumar S (2011) Biogas Technology: towards sustainable development. TERI Press, New Delhi Google Scholar

- Friman R (1984) Monitoring anaerobic digesters on farms. J Agricult Eng Res 29:357–365 ArticleGoogle Scholar

- Hennessy J, Eriksson O (2015) Energy and nutrients from horse manure: life-cycle data inventory of horse manure management systems in Gävleborg, Sweden

- MitikuTeferra D, Wubu W (2019) Biogas for clean energy. Anaerobic Digestion. IntechOpen, London Google Scholar

- Mule dung to replace LPG - Early Times Newspaper Jammu Kashmir n.d. http://earlytimesnews.com/newsdet.aspx?q=86999 (accessed August 11, 2020).

- Uche OAU (2007) The effect of donkey-dung on the properties of lateritic soilcrete blocks. J Eng Technol 2:45–54 Google Scholar

- Camel dung fuels cement production in northern UAE - Reuters n.d. https://www.reuters.com/article/us-emirates-energy-camels/camel-dung-fuels-cement-production-in-northern-uae-idUSKCN1UG0GR (accessed August 11, 2020).

- Laskri N, Mizi A, Daas D, Nedjah N, Baccouche M (2016) Biogas production from the anaerobic digestion of lignocellulosics wastes. Pollut Res 35:247–252 Google Scholar

- Rhode D, Madsen DB, Jeffrey Brantingham P, Dargye T (2007) Yaks, yak dung, and prehistoric human habitation of the Tibetan Plateau. Develop Quater Sci 9:205–224 Google Scholar

- Joshi R, Ahmed S (2016) Status and challenges of municipal solid waste management in India: a review. Cogent Environ Sci 28:1139434 ArticleGoogle Scholar

- Resource Assessment for Livestock and Agro-Industrial Wastes-India Prepared for: The GlobalMethaneInitiative2011.https://www.globalmethane.org/documents/ag_india_res_assessment.pdf (accessed August 11, 2020).

- Tanksali AS (2013) Treatment of sugar industry wastewater by upflow anaerobic sludge blanket reactor | Request PDF. Int J ChemTech Res 5:1246–1253 Google Scholar

- Sahu O, Rao DG, Gopal R, Tiwari A, Pal D (2017) Treatment of wastewater from sugarcane process industry by electrochemical and chemical process: aluminum (metal and salt). Journal of Water Process Engineering 17:50–62 ArticleGoogle Scholar

- By-products of Sugarcane n.d. http://content.indiainfoline.com/wc/archives/sect/suin/ch10.html (accessed August 11, 2020).

- Mohana S, Acharya BK, Madamwar D (2009) Distillery spent wash: treatment technologies and potential applications. J Hazard Mater 163:12–25 ArticleGoogle Scholar

- Kharayat Y (2012) Distillery wastewater: bioremediation approaches. J Integr Environ Sci 9:69–91 ArticleGoogle Scholar

- Mohan N (2021) Prospects of ethanol & its costing. National Sugar Institute, Kanpur Google Scholar

- Shete BS, Shinkar NP (2017) Anaerobic digestion of dairy industry waste water-biogas evolution-a review. Int J Appl Environ Sci 12:1117–1130 Google Scholar

- Kolev SA (2017) General characteristics and treatment possibilities of dairy wastewater–a review. Food Technol Biotechnol 55:28 Google Scholar

Acknowledgements

The authors would like to thank Mr. Siddhant Dash and Mr. Ankit Pratim Goswami, Department of Civil Engineering, Indian Institute of Technology Guwahati, Assam (India), for giving valuable comments and proof read which helped in improving the manuscript.